Custom Conveyors, Belting, & Rollers

We are a distributor for Omni Metalcraft, standard & custom conveyors, with other vendors providing custom roller and belting options suitable for multiple industries including food processing. There are many different types of conveyors-gravity, chain, belt, and live roller (belt driven, chain driven, line shaft driven).

Gravity conveyor is an economical solution for product transport, handling products of a wide variety of sizes and weights. Applications include staging and/or transportation of products. Gravity can come in standard roller, flow rail, or skate rail.

Chain is used to move product that will not convey on rollers. It is ideal for wrong-way pallets, racks, automobile frames, and others needing a sturdy conveying surface. Custom chain includes double pitch, multi strand, attachment chain, urethane puck, stainless steel, corrosion resistant, and CCS.

Belt conveyors increase efficiency for assembly lines, sorting, inspection, and transportation. Applications include moving bulky boxes, furniture, wood sheets, totes, and packaged goods.

The live roller conveyors are either belt drive, chain driven, or line shaft. They are more versatile, handling heavy loads and accumulate, divert, merge, and transport various products.

Belting Options

We can provide specialized belting solutions from Beltservice, and INO Belting. This includes light duty, heavy duty, incline, interwoven PVC, felt (Kevlar), and more.

Light duty compounds available are rubber, nitrile, leather, silicone, butyl, Teflon, PVC, and FS. Different covers encompass FDA/USDA regulation, extreme temperature, oil and fat resistance, cut and abrasion resistance.

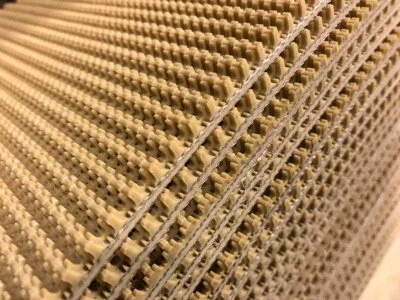

We also offer conveyor belting that has fabric based products. The product range includes tubes, pads, belts, and felt timing belts. Material can be PBO outside + Kevlar inside, Kevlar, Nomex, and polyester. These materials are designed specifically for the Aluminum Extrusion industry (they can resist temperatures up to 600 Celsius instantaneously) and transport profiles of various shapes and weights.

Whatever your application, we think you’ll find the belt you need from one of these two manufacturers.

Roller Options

We are distributors for two roller manufacturers, Finzer Roller and Cent-Roll each with their own niche in the marketplace, providing both supply roller and roller coverings for specific industry standards. Appropriate for use in lines for plastic, glass, steel, paper, building materials, hygienic products, and food processing.

Coatings include rubber, chrome (mirror and matte finish, wet or dry), Teflon, urethane , plasma, E-Nickel, black oxide, and anodize.

Whatever your roller/roller covering needs are, you’ll be able to find the solutions here.